Comment tout a commencé ?

L’histoire de notre production commence il y a quelques années, au printemps 2018, lorsque nous avons commencé à travailler avec un agent au nord du Portugal. Au début, nous n'étions que quatre, mais nous avions une vision claire de notre objectif : créer des produits de qualité, durables et pratiques tout en respectant l'environnement. 🌳

Compte tenu des spécificités techniques de nos produits, notre métier est devenu une expertise à part entière, et c'est ainsi que nous avons recruté nos deux premières employées : Pauline et Justine. Grâce à leur arrivée, nous avons pu élargir notre gamme de produits en proposant des vêtements pour femmes, enfants, hommes, etc. Nous avons ainsi pu commercialiser plus de 100 références en 2021, tester de nouveaux produits et matières pour répondre aux demandes de nos clientes. 🤰🏽

Nous avons encore aujourd'hui une centaine de développements par an, répartis sur plusieurs lancements. En règle générale, nous avons un lancement de collection par mois.

Notre équipe de production est maintenant composée de cinq personnes. Justine est responsable de la production et s'assure que chaque étape est réalisée de manière efficace. Marine et Fanny travaillent à ses côtés pour assister dans l'organisation et la coordination de la production. 💻

Pauline est responsable de la collection et est chargée de la recherche d'inspiration et de la création des plans de collection. Elle suit le produit de son imagination à sa commercialisation en prenant part aux photos shootings des collections. 📸

Hélène s'occupe du style pour s'assurer que chaque produit correspond à l'image de marque et à la vision de la collection. 🍌

Enfin, Clémentine est notre modéliste/technicienne produit, chargée d'envoyer les dossiers techniques aux fournisseurs et de s'assurer que chaque produit est conforme à nos attentes. 📒

La qualité et la praticité de nos produits ont toujours été au cœur de nos préoccupations. Nous avons donc mis en place des processus rigoureux pour garantir que chaque produit répond aux normes les plus strictes en matière de qualité et de sécurité. C'est pourquoi nous avons voulu organiser un échange en visio avec vous pour répondre à toutes vos questions et vous montrer la passion que nous avons pour notre métier et pour la création de produits de qualité. 👌🏼

Les grandes étapes du développement d’un nouveau produit

Notre processus de production est un élément clé de notre entreprise. Il nous permet de créer des produits de qualité, respectant nos

valeurs éthiques et environnementales. Nous suivons un processus en 5 étapes, de la création de produits à la livraison en passant par le sourcing des fournisseurs, le développement du produit et le lancement de production.

1️⃣ La première étape consiste en la création de produits. Notre équipe de création composée d'Alison, fondatrice de Tajinebanane ainsi que Pauline et Hélène, recherche l'inspiration et les matières premières pour élaborer un plan de collection. Cette étape est cruciale car elle détermine la direction que prendra la collection. ✍🏽

2️⃣ La deuxième étape est le sourcing des fournisseurs. Nous choisissons nos fournisseurs en fonction de critères rigoureux tels que la production européenne et leur engagement à respecter notre cahier des charges élaboré par Intertek, un organisme indépendant de qualité. Nous travaillons avec des fournisseurs situés en Italie, Bulgarie, France et Portugal car chaque pays a sa spécificité et sa force, et c'est ce que nous recherchons. A titre d’exemple, nous réalisons tous nos produits en Jersey au Portugal, nos produits en maille en Italie, etc. 🏭

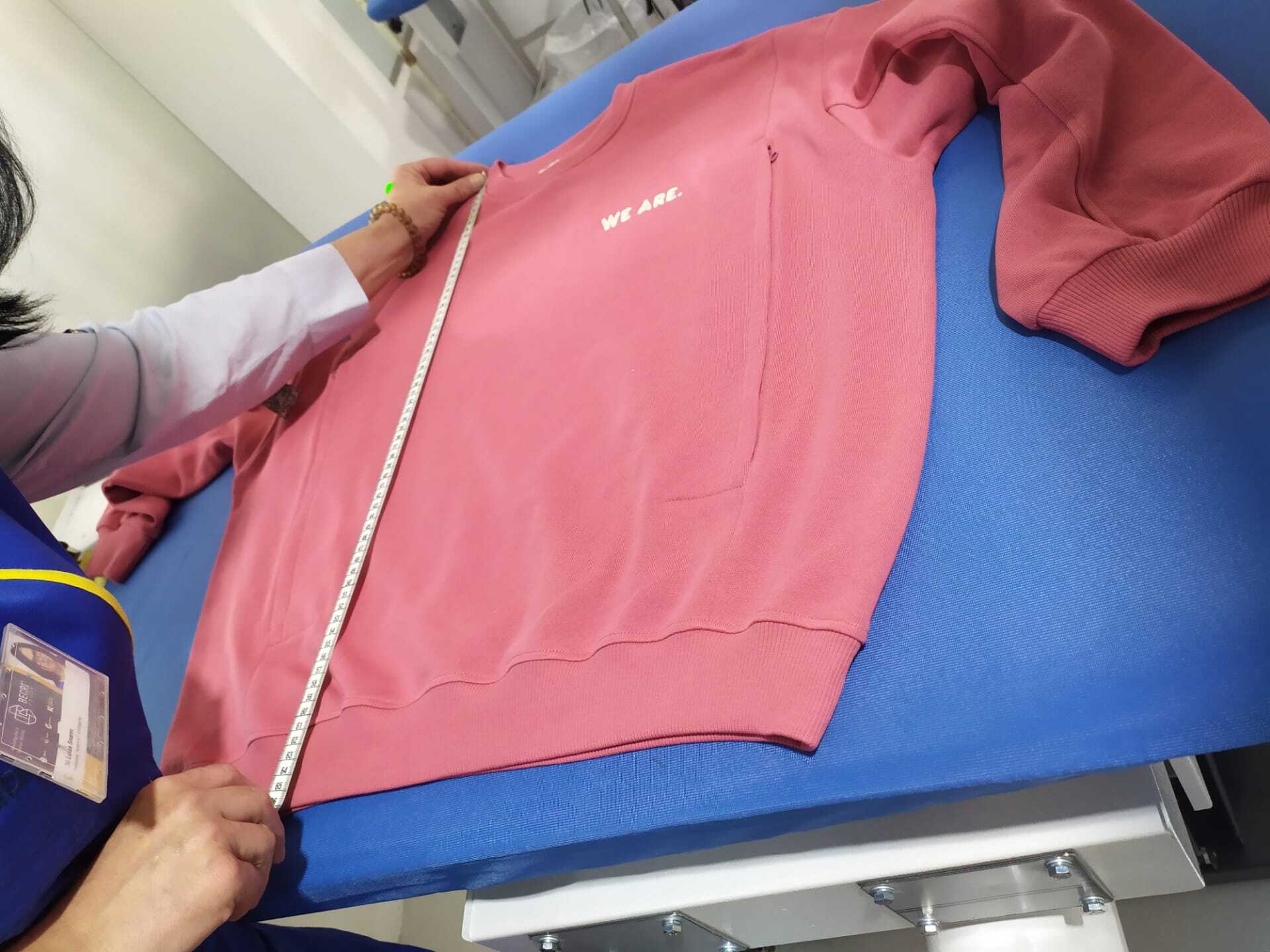

3️⃣ La troisième étape est le développement du produit. Notre technicienne produit envoie des dossiers techniques aux fournisseurs choisis avec tous les détails nécessaires tels que la composition, la broderie, l'impression, les mesures, etc. Nous recevons ensuite un premier proto que nous essayons, mesurons et testons pour qu'il réponde à nos attentes. Il peut y avoir entre 1 à 3 itérations par modèle. En règle générale, lorsque nous en sommes au 3e protos et qu’il n’est toujours pas conforme, nous annulons le modèle. 👚

4️⃣ La quatrième étape est le lancement de production. Si tout est ok avec le proto, nous lançons une tête de série pour valider la gradation de notre produit. Nous ne lançons jamais une production sans recevoir ces pièces. Pendant ce temps, nous commandons les modèles validés et recevons un échantillon de matière de production pour valider la conformité de la matière.

Si la tête de série, l'échantillon de matière et les accessoires sont ok, nous lançons la production. Il faut compter entre 5 et 8 mois pour produire nos collections. ✅

5️⃣ Enfin, la dernière étape est la livraison. Avant chaque départ de marchandise, nous recevons des pièces pour valider la conformité et nous effectuons un contrôle qualité à réception de la marchandise dans notre entrepôt en effectuant des prélèvements aléatoires. Cette étape est cruciale car elle garantit que le produit est conforme à nos attentes et aux normes de qualité. 📦

En conclusion, notre processus de production en 5 étapes nous permet de produire des produits de qualité tout en respectant nos valeurs éthiques et environnementales. Nous sommes fiers de travailler avec des fournisseurs respectueux des normes et de garantir un contrôle qualité rigoureux pour chaque produit livré.

Quelles sont les grandes étapes de confection d’un tee-shirt

La confection d'un tee-shirt en coton nécessite des étapes précises et minutieuses pour obtenir un produit final de qualité, résistant et confortable. Les différentes étapes sont toutes essentielles pour que le produit final soit en accord avec les attentes des clients.

1. Sélection des matières premières : Pour fabriquer un tee-shirt blanc en coton, il est nécessaire de sélectionner une matière première de qualité. Le coton peut être cultivé dans de nombreux pays, et il existe de nombreuses variétés de coton. En fonction des besoins du produit final, il est important de choisir un coton de qualité qui sera confortable, doux et durable. ☁️

2. Teinture du fil, le fil en coton brut est ensuite teint dans la couleur du produit fini. 🧵

3. Tricotage du jersey :Une fois le fil teint, il est tricoté en utilisant une machine spéciale. Le jersey doit être tricoté avec une densité adaptée pour qu'il soit résistant, confortable et agréable à porter. 🪡

4. Réalisation du patron : Le patron du tee-shirt est créé sur papier ou sur ordinateur, en fonction des mesures standard pour chaque taille. 👚

5. Découpe du jersey : Le jersey est ensuite découpé en fonction du patron, en prenant soin de respecter les orientations des fils. Cette étape est importante pour que le tee-shirt ait la bonne taille et la bonne forme, et pour minimiser les pertes. ✂️

6. Assemblage : Les différentes parties du tee-shirt (manches, col, devant, dos) sont assemblées grâce à des machines à coudre spécialisées. Les coutures sont réalisées en prenant soin de les rendre résistantes pour que le tee-shirt puisse supporter les mouvements et les lavages répétés. 🧼

7. Finitions : Une fois assemblé, le tee-shirt passe par une étape de finition pour enlever les fils en trop et les petites imperfections. Les coutures sont également vérifiées pour s'assurer qu'elles sont parfaitement droites et résistantes. 🪡

8. Étiquetage et emballage : Le tee-shirt est ensuite étiqueté avec des informations sur la taille, la composition, les instructions de lavage, etc. Il est ensuite plié et emballé dans une polybag recyclé et recyclable pour être prêt à être expédié aux magasins ou aux clients. 📦

9. Shooting et mise en ligne : Nos produits sont vendus à travers le monde pour soutenir vos allaitements, familles, partout. Tout. le temps.